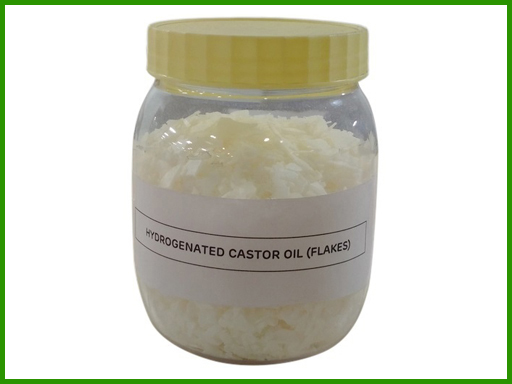

Hydrogenated Castor Oil – HCO (Flakes Form)

Hydrogenated Castor Oil is manufactured by adding hydrogen to refined Castor Oil in the presence of a nickel catalyst, the resultant oil is called Hydrogenated Castor Oil. After filtration, the liquid HCO goes either to Flaking machine to get HCO Flakes or to Spray Drying Tower to get HCO Powder. After filtration it is transformed into a hard, brittle wax with a melting point of approximately 85-86 degrees Centigrade. This wax is extremely insoluble and is therefore well suited for products needing resistance to water, oils, petroleum and petroleum derivatives.

HCO is available as flakes or powder which melts to a clear transparent liquid. It is a non-toxic, non-hazardous material. Hydrogenated castor oil is used in manufacturing of greases, but it may also be used in a paper coating for food packaging. The product can be available with several different melting points, or in beaded or powdered form. Partially Hydrogenated castor oil is used in cosmetic formulations such as lipsticks and stick deodorants.

Application

Hydrogenated Castor Oil finds a number of diversified uses due to its unique combination of physico-chemical properties.

- In the manufacture of multipurpose Lithium/Calcium grease and high-performance aviation grease.

- In the manufacture of soaps & cosmetics.

- As mould release agent in the processing of plastics and rubbers.

- As a component of specialty wax blends like pencils, crayons, lipsticks and anti-deodorant sticks.

- In the manufacture of hot-melt coatings and sealant requiring resistance to water.

- As a coating agent for paper & as anti-foaming agent.

- In the manufacture of Automotive refinish Acrylics.

- Rheological agent that provides thixotropic in paints, coatings, inks, adhesives, sealants and numerous industrial compositions.

- Thick film chlorinated rubber, epoxy and vinyl coating.

- Flame Retardant and anti-static agent for fiber.

- Manufacture of Spin finish oil for polyamide fiber.

- In preparation of ointments, emulsified virus vaccines, sustained release capsules, wetting/bodying agent, face paint.

- As plasticizer for cellulosic.

- Processing aid for Colour concentrates.

- Surface treatment agents.

- In the manufacture of hot melt adhesives used in packaging books, binding footwear and in carpet backing

- Anti-tack and slip additives for processing plastics

- In the manufacture of specialty chemicals for applications such as metal working, plasticizers and textile auxiliaries in the form of derivatives such as esters, ethylates, sulphates etc.